Kima Chemical, as a leading HPMC factory, plays a crucial role in providing high-quality Hydroxypropyl methyl cellulose ether HPMC products to various industries worldwide. Its commitment to quality, sustainability, innovation, and a customer-centric approach ensures that Kima Chemical remains at the forefront of the cellulose ether industry.

1. Introduction

1.1 What is HPMC?

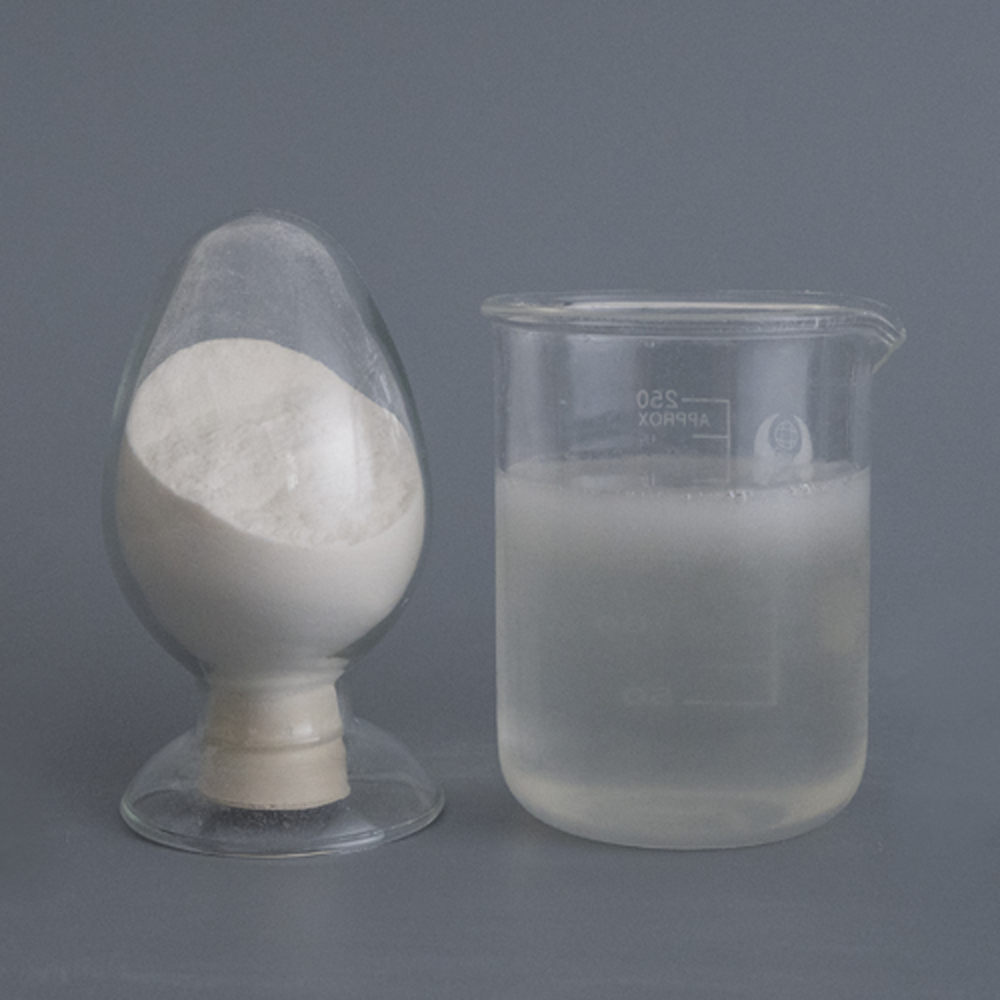

Hydroxypropyl Methylcellulose, commonly

known as HPMC, is a versatile and widely used cellulose ether. It is

derived from cellulose, a natural polymer found in the cell walls of

plants. HPMC is produced by modifying cellulose through a series of

chemical processes, resulting in a compound that offers a broad range of

applications. It is known for its water-soluble and film-forming

properties, making it valuable in industries such as construction,

pharmaceuticals, food, cosmetics, and more.

1.2 The Role of HPMC in Various Industries

The adaptability of HPMC has made it a fundamental ingredient in many industries:

-

Construction: HPMC is crucial in the formulation of construction

materials, including cement-based mortars, tile adhesives, and

skimcoats. It enhances properties such as workability, adhesion, and

water retention.

- Pharmaceuticals: In the pharmaceutical

industry, HPMC is used in drug formulations, where it serves as a

binder, disintegrant, and controlled-release agent. It contributes to

the overall quality and efficacy of pharmaceutical products.

-

Food and Cosmetics: HPMC is a common additive in food products, acting

as a thickener, stabilizer, and emulsifier. It is also used in cosmetics

and personal care products, where it provides texture and consistency.

1.3 About Kima Chemical

Kima

Chemical is a leading HPMC factory specializing in the production of

Hydroxypropyl Methylcellulose. With a commitment to quality,

sustainability, and innovation, Kima Chemical has established itself as a

global player in the cellulose ether industry. This comprehensive guide

explores Kima Chemical's operations, from the production of HPMC to its

applications in diverse industries, and the company's dedication to

delivering high-quality cellulose ether products to meet the demands of a

dynamic market.

2. HPMC Production: From Cellulose to Ether

2.1 The Basics of HPMC Manufacturing

The production of HPMC

involves a series of chemical processes that transform cellulose into a

water-soluble polymer with diverse properties. The key steps in HPMC

manufacturing include etherification, purification, and drying.

2.2 The Raw Material: Cellulose

Cellulose,

a natural polymer, is the primary raw material for HPMC production. It

is sourced from plant materials, typically wood pulp or cotton, and

undergoes rigorous processing to extract the cellulose chains.

2.3 Etherification Process

The

etherification process involves the chemical modification of cellulose

through the introduction of propylene oxide and methyl chloride. This

results in the creation of hydroxypropyl and methoxy groups on the

cellulose chain. These modifications impart unique properties to the

cellulose, making it water-soluble, thermally reversible, and

film-forming.

2.4 Quality Control and Assurance

Ensuring the quality and

consistency of HPMC products is a critical aspect of the manufacturing

process. Kima Chemical, like other reputable HPMC manufacturers,

implements strict quality control measures to guarantee that the final

product meets the necessary standards. This includes testing for

parameters like viscosity, moisture content, and particle size.

3. Kima Chemical: A Global HPMC factory

3.1 Kima Chemical's History and Background

Kima

Chemical has a rich history in the production of cellulose ethers,

particularly HPMC. With years of experience and a commitment to

excellence, Kima Chemical has evolved into a prominent player in the

industry.

3.2 Global Presence

Kima Chemical

serves a global customer base, reaching various regions and markets. Its

wide distribution network ensures that high-quality HPMC products are

accessible to customers worldwide.

3.3 Commitment to Quality and Sustainability

Kima Chemical's

commitment to quality is evident in its production processes and

stringent quality control measures. Additionally, the company places a

strong emphasis on sustainability and environmentally responsible

practices. This includes sustainable sourcing, green initiatives, and

eco-friendly manufacturing processes.

4. The Diverse Applications of HPMC

4.1 HPMC in the Construction Industry

HPMC plays a pivotal

role in the construction industry by enhancing the performance of

various materials, including cement-based mortars, tile adhesives, and

skimcoats. Its functions in this industry encompass water retention,

binding, thickening, and setting time control. The result is improved

workability, adhesion, and surface smoothness in construction materials.

4.2 HPMC in Pharmaceuticals

In

the pharmaceutical industry, HPMC is an essential ingredient in drug

formulations. It serves as a binder, disintegrant, and

controlled-release agent, contributing to the overall quality and

effectiveness of pharmaceutical products.

4.3 HPMC in Food and Cosmetics

The

food industry benefits from HPMC as a versatile additive. It functions

as a thickener, stabilizer, and emulsifier in various food products.

Additionally, HPMC is used in cosmetics and personal care products,

where it provides texture, consistency, and stability.

4.4 Emerging Applications

HPMC's

adaptability continues to drive its use in emerging applications. As

industries evolve, HPMC may find new roles in areas such as 3D printing,

textile printing, and more.

5. Innovation and Research at Kima Chemical

5.1 R&D Facilities

Kima Chemical invests in research and

development (R&D) to improve existing products and develop new

formulations. State-of-the-art R&D facilities are dedicated to

exploring the full potential of cellulose ethers, leading to innovation

in HPMC applications.

5.2 Customized Solutions

Kima

Chemical offers customized solutions to meet the unique requirements of

customers. The company's technical expertise and the flexibility to

tailor HPMC products enable customers to achieve optimal results in

their specific applications.

5.3 Adapting to Industry Trends

Kima

Chemical remains attuned to industry trends and technological

advancements. By staying current with market demands and emerging

applications, the company continues to provide valuable cellulose ether

products that meet the evolving needs of various industries.

6. Quality Control and Certifications

6.1 Quality Control at Kima Chemical

Kima

Chemical follows rigorous quality control measures throughout the

production process to ensure the quality and consistency of HPMC

products. Parameters such as viscosity, moisture content, and particle

size are closely monitored.

6.2 Regulatory Compliance

Kima

Chemical's HPMC products are designed to comply with relevant industry

regulations and standards. This commitment to regulatory compliance

provides customers with confidence in the safety and quality of the

materials they use in their projects.

6.3 Industry Certifications

Kima

Chemical's adherence to quality and safety standards is further

demonstrated through industry certifications and qualifications. These

certifications underscore the company's dedication to providing products

that meet the highest industry standards.

7. Sustainability and Environmental Responsibility

7.1 Eco-Friendly Practices

Sustainability

is a top priority for Kima Chemical. The company implements

eco-friendly manufacturing practices, including waste reduction and

responsible resource management.

7.2 Sustainable Sourcing

Kima

Chemical places great emphasis on sustainable sourcing of raw

materials. This commitment ensures that the production of HPMC remains

environmentally responsible and sustainable.

7.3 Green Initiatives

The

company participates in various green initiatives, aiming to minimize

its environmental footprint and contribute to a cleaner, more

sustainable planet.

8. Customer-Centric Approach

8.1 Technical Support and Expertise

Kima

Chemical is dedicated to providing exceptional technical support and

expertise to its customers. This support assists customers in choosing

the right HPMC grade for their projects, ensuring that they achieve the

desired results.

8.2 Tailored Solutions

The

flexibility of Kima Chemical allows for the provision of tailored

solutions. The company works closely with customers to address their

specific needs, offering customized HPMC products and expert guidance.

8.3 Building Strong Customer Relationships

Kima

Chemical prioritizes building and maintaining strong customer

relationships. By understanding the unique requirements of each

customer, the company can deliver exceptional service and the most

suitable cellulose ether solutions.

9. Challenges and Opportunities in the HPMC Industry

9.1 Market Challenges

The

HPMC industry faces challenges, including fluctuations in raw material

prices and the availability of alternative materials. Additionally,

keeping up with evolving industry regulations and standards is

essential.

9.2 Opportunities for Growth

Despite

challenges, the HPMC industry presents numerous opportunities for

growth. The expanding construction industry, the demand for sustainable

materials, and emerging applications in various sectors offer

significant prospects for HPMC manufacturers.

9.3 Industry Trends

Staying

current with industry trends is vital for HPMC manufacturers. Trends

such as sustainability, technological advancements, and the development

of new applications continue to shape the cellulose ether industry.

10. Conclusion

In conclusion, With a global presence and a

dedication to environmental responsibility, Kima Chemical is

well-positioned to meet the evolving needs of its customers and the

dynamic demands of the market. As industries continue to evolve,

cellulose ethers like HPMC will remain indispensable in various

applications, offering versatility and reliability in a wide range of

sectors.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland